The Ferrari was the real star. To a tension-filled soundtrack of brass and synth, Magnum chased down murderers, drug traffickers, spies, assassins, and more in that Ferrari, leaving nothing but a trail of dust behind him. In 1984, its V8 engine boasted 230 horsepower.

Today, a V6 Toyota Camry packs over 300 HP.

The Great Acceleration

No one’s chasing down bad guys in their Camry. How could America’s dream car — an exotic fantasy machine of efficiency, speed, and mustachioed justice — pale in comparison to an average sedan produced only a few decades later?

Since the 1960s, the average horsepower and torque of passenger vehicles sold in the U.S. skyrocketed in what is sometimes called “The Horsepower Wars.” Spurred by technological progress and sales trends, from 1980 to 2010, the average engine power for passenger vehicles sold in the US increased by 112%. It didn’t stop there.

Major global events — such as fluctuating oil prices and industrial regulation — have slowed this great acceleration down at times, but nothing has stopped it entirely. And now, the American automotive market’s embrace of electric-powered vehicles is ready to charge things up all over again.

Keeping Up

Cars are highly interconnected machines. If you’ve ever tuned a vehicle, you know. Everything has a ripple effect. If you change the engine, you’re going to have to adjust other elements to suit it. This is absolutely true when it comes to tires. And it’s not just race cars. As passenger cars evolve, so must passenger tires.

Even with all the power in the world under your hood, if your tires can’t properly translate that power into acceleration, what’s the point? To rein in all those horses, you need a strong grip.

So, right alongside the decades-long trend of increasing engine power, the tire industry had to problem-solve, building better and better tires to keep up with all that extra power. To date, many of those innovations came from the worlds of racing and the production of performance tires.

“Performance” Today, “Passenger” Tomorrow

During this technological advancement, a pattern emerged: If today’s daily drivers have the power of yesterday’s sports cars, then, today’s “performance” tires are tomorrow’s “passenger” tires. Perhaps without even realizing it, whatever you have in your garage today is running performance tire technology.

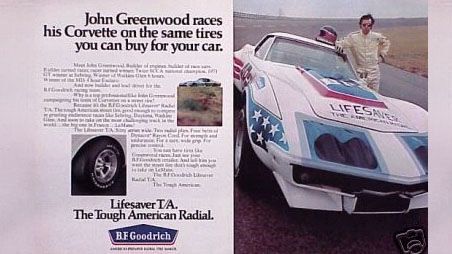

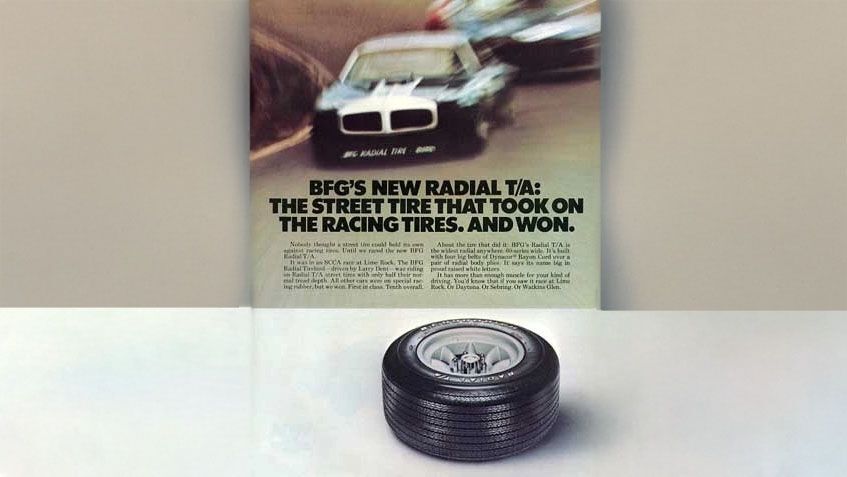

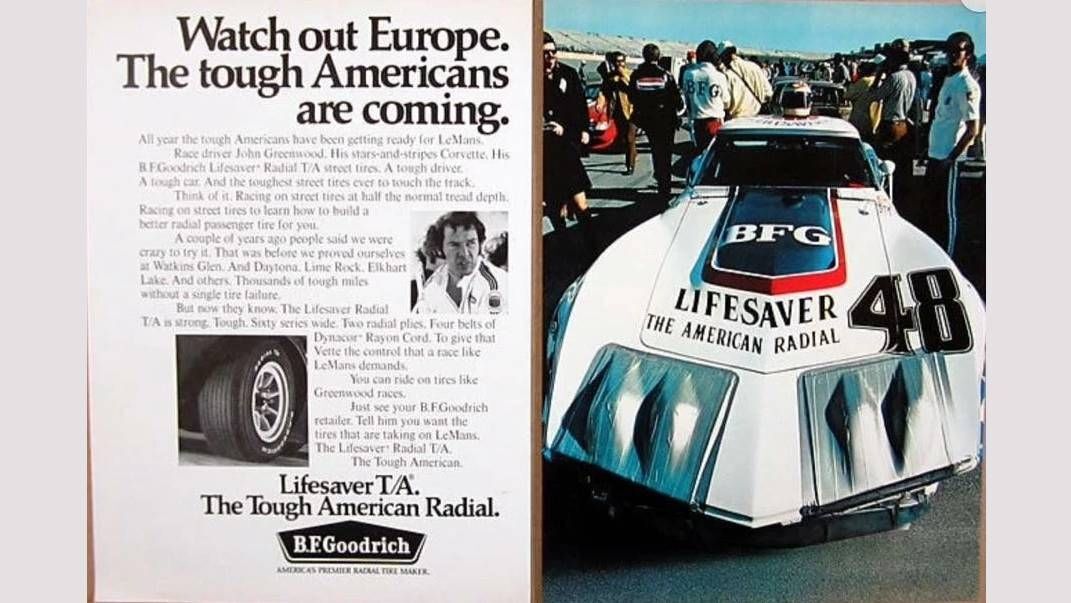

As a dedicated leader in high-performance tire technology, BFGoodrichⓇ Tires was right there for critical moments during the horsepower wars. In 1965, they introduced the first American-made radial tire, bringing performance gains to the American car scene and enabling the muscle car-era engines to start upping the HP ante.

The Lifesaver was the first 60-series tire designed for the street — specifically, for the popular and increasingly powerful muscle cars of the day. (A 60-series tire features a sidewall that is 60% as tall as the tire's section width.) But to prove the tire could handle anything, they brought it to the track, racing the tires on Pontiac Firebirds in the 1970 SCCA National road racing series. At Watkins Glen, they had a historic class win — and they did it on a set of tires that they could drive home after the race.

“Average vehicles today can accelerate faster than any car in the history of the automobile. Suddenly, everyone needs a high-performance tire. And that's where BFGoodrich comes in. Starting in the seventies right up to today, the BFGoodrich engineers have translated all of their experience from racing and performance tire production into what has become the modern passenger tire.” – Andrew Comrie-Picard

The Trade-Offs of Translation

This is a delicate process. A typical CUV sold in the US today is well over 4,000 pounds, and many have the horses to go from zero to sixty in under five seconds. Nothing about that equation is quiet or smooth. But, noise and rider comfort are key features that consumers look for when purchasing vehicles and tires. Passenger tires are also expected to perform in a much broader range of terrains (asphalt, cement, gravel, etc.), environmental conditions (snow, rain, ice, etc.), and ambient temperatures than racing tires.

So, the trade-offs begin. Like a mechanic carefully tunes a race car, tire engineers tweak and measure different tread patterns, construction techniques, and rubber compounds in search of the perfect array of desired qualities, from right out the gate and over time.

“There are over 200 components in a tire, and usually at least four types of rubber, all of which have to be vulcanized together — a process that never fully stops. They continue to cure and age over time. That piece alone is a very complicated bit of engineering. And it’s all hidden within what looks like a simple black donut.” – Andrew Comrie-Picard

The Pattern Repeats

Recent decades have seen dynamic leaps forward in tire technology, especially in the manufacturing techniques and rubber compounding areas. BFGoodrich Tires engineers, industrial designers, and everyone involved in the racing programs have been hard at work spurring this progress forward, matching the power of the automotive industry along the way.

“Not only is a modern Toyota Camry faster than a race car was in the 1970s, but the tires are many times more sophisticated than those tires were back in the day. I’d argue that we're not only keeping up with the technological advancements in vehicles. We're lapping them.” – Andrew Comrie-Picard

But even if there is a bit of a lead, this work is far from over. As progress continues and electric cars become commonplace, cars will be faster than ever, and consumers will continue to demand tires that are durable and long-lasting.

A whole new world of tire engineering challenges awaits.

And we’re ready for it.